Manufacturing

Return to the Manufacturing Project List

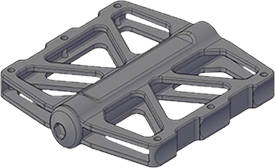

Project 4: Design and Production of a Bicycle Pedal for BMX Bikes

Project Overview

Purpose:

The purpose of this project is to incorporate employability skills (teamwork, problem solving, verbal communication, written communication, dependability/work ethic, and planning and organizing skills) into activities that are related to the design and basic production quality control for BMX bike pedals.

The purpose of this project is to incorporate employability skills (teamwork, problem solving, verbal communication, written communication, dependability/work ethic, and planning and organizing skills) into activities that are related to the design and basic production quality control for BMX bike pedals.

This project is divided into four main activities:

- Activity 1: Design of the part with the use of CAD/CAM tools (Autocad 2017), with existing technical specifications and using two different units of measurement (millimeters and inches). The project teams will execute the design.

- Activity 2: CNC programming will be used (including specific hardware and software tools) for final production of the CAD designed part (produced from Activity 1). During this activity, the project team uses earlier data to provide general guidelines for the correct connection process for CNC hardware (steps for the connection of the hardware need to be analyzed and correctly organized prior to final execution). Several samples of the pedal will be produced.

- Activity 3: Quality control for manufactured bike pedals (produced from Activity 2). The company team is now responsible for executing quality control over the finished parts. The company is known for having experience on implementing Statistical Process Control (SPC) as a tool for quality assessment (working with tolerances and application different Cpk indicators, for example 1.33, 1.67 & 2.0).

- Activity 4: The company team will deliver a final official presentation to the CEO of the company for final approval of the pedal. The team will introduce the main ideas for the project as well as main details of each prior executed activity (1, 2 and 3). As part of the presentation responsibilities, the team will be in charge of contacting the A/V department to take care of the presentation’s technical needs (video projector, computer, etc.). As part of the presentation scenario, an instructor may choose to introduce a “bug” or technical problem with the presentation equipment (i.e., unplugged or switched video projector/computer cables, etc.) for the presentation team to work through and solve to make the presentation equipment operable.

Courses for Implementation:

- Introduction to Autocad

- Introduction or Fundamentals of Engineering

- Advanced Technology concentration courses

- Manufacturing concentration courses

- Quality Control courses

Key Terms/Major Topics:

Mechanical Assembly (Mechatronics)

- Bicycle pedal for BMX bikes (basic definition, function, operation, general technical specifications)

- Computer Aided Design (CAD)

- Computer Aided Manufacturing (CAM)

- Statistical Process Control (SPC standard) as quality control tool widely used in industry for manufacturing processes

- Conversion between system units (inches versus millimeters)

- Basic Computer Numerical Control (CNC) programming, software and hardware associated, CNC programming standards

- Mechanical properties of materials (ASTM standards)

Equipment/Materials:

- Standard classroom technology equipment (computer, projector, etc.)

- Computer with CAD/CAM software (for this project the use of Autocad 2017 is suggested)

- Computers with presentation software (Microsoft PowerPoint, Apple Keynote, Powtoon or Prezi, etc.)

- Plotter or printer

- Milling machine

- 3D printers

- Micrometers

- Measurement tapes